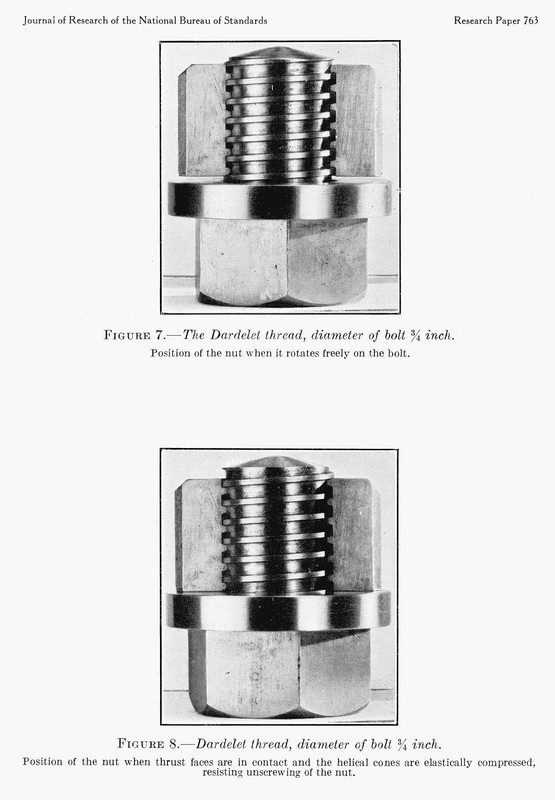

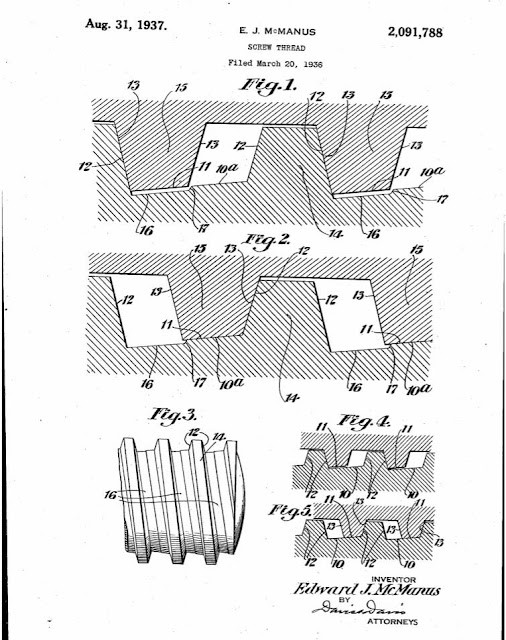

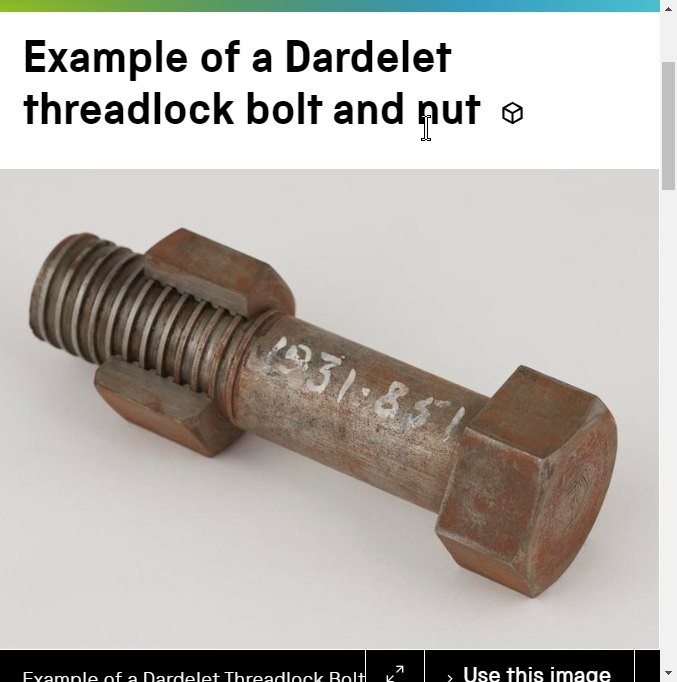

Wow。看到这种1930 年代非常流行的自锁螺丝,mindboggling,sophisticated,看起来像是ACME 传动蜗杆,但是每个螺纹都有正锥度反锥度和小坡度,有了ACME 的超强转矩和minimal backlashing,但还有很强力的自发锁紧(ACME 之所以只能传动就是不容易倒转但也不容易锁紧,这个是既不可能倒转尤其还自发锁紧防震,sophisticated,mind boggling)

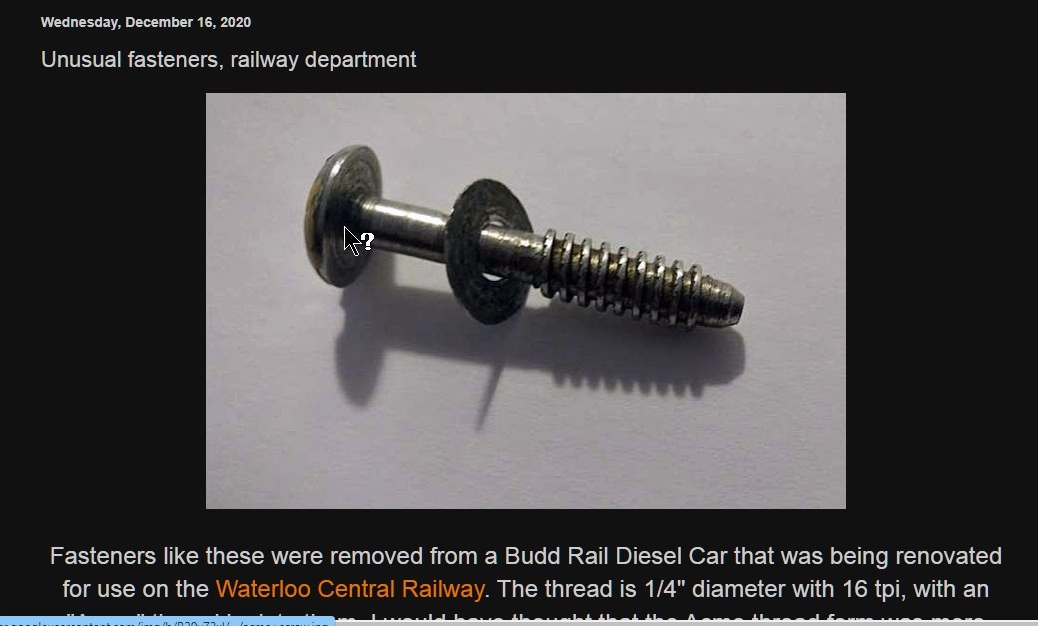

关键是古代1930 年代这种叫Dardelet Bolt 居然数量不少非常流行,火车铁路和海事平台都惯用这种螺丝!矿业机械和潜艇和潜水工事也有使用。想想那个远古年代,车床可能还有相当数量是蒸汽动力驱动的,只要有追求连个螺纹都能这么标新立异啊。。。

翻老期刊,好像强度也不错!

In all cases the impact work for bolts with American National coarse threads was less than for bolts of the same size and material with American National fine threads. Except for the brass bolts and those cold-rolled steel bolts which showed brittle failures, the impact work for bolts with American National fine threads was approximately the same as for bolts of the same size and material with Dardelet threads. In all cases the impact work for bolts with Dardelet threads was much greater than for bolts of the same size and material having American National coarse threads.

Similar relations were observed for the static work and the maximum static load.

Beyer [4] made static tensile and tensile impact tests on cold-drawn steel bolts having Dardelet and U. S. Standard threads. He reported that bolts having Dardelet threads gave greater static tensile strength, greater stretch, and greater resistance to impact than similar bolts having U. S. Standard threads.

战后也一直作为高强度螺丝使用。比如海上平台,水下工事,一直使用到 60年代。在不方便像飞机那样可以允许多花工时穿孔锁紧的情况下,这种螺丝战斗力比普通螺丝强得多。

就是不利于批量生产,一般批量挤压和批量车铣都不好弄。当然手工或CNC 加工都可以做,但也要几倍工时,现在因为成本被完全淘汰了,大概70s 以后彻底绝迹了;就是没想到古代大量使用的上古螺丝、技术和战斗力和人机工效方便都远远超过了现代产品,真要比能接触到的普通螺丝质量,现代普通人竟然比不上100年前